In mechanical design, many mistakes can occur, such as fabricating incorrect parts, drilling wrong holes, omitting dimensions, or selecting undersized motors. It’s essential to pay attention to easily overlooked details in the design process:

-

Design Lubrication Points for Rotating Parts

-

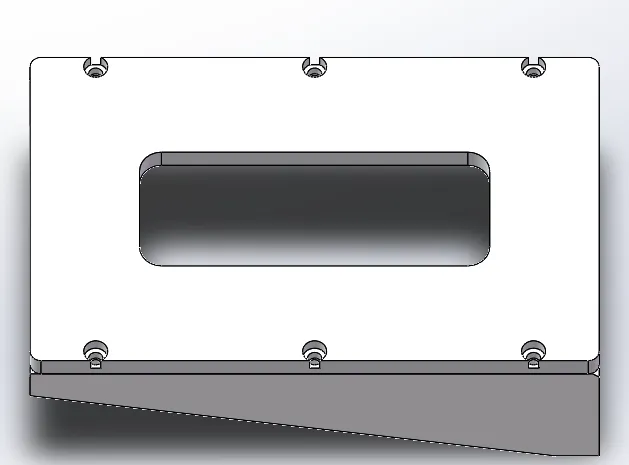

Design Safety Covers for Rotating Parts (Include Observation Windows)

-

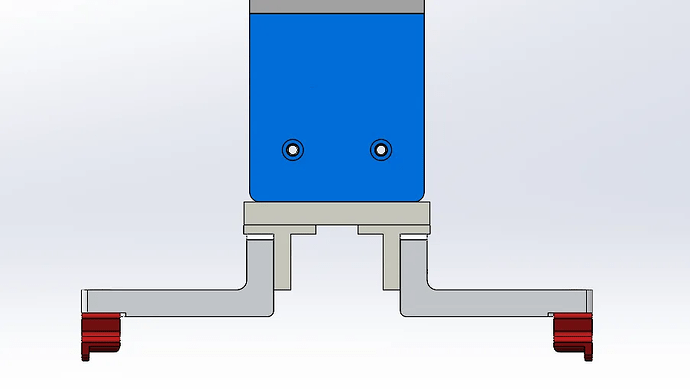

Design Lifting Holes or Lifting Ears for Components Over 20 kg

- Safety: Lifting holes or ears ensure that components can be securely and safely lifted, avoiding accidental drops or damage.

- Convenience: They provide convenient attachment points for lifting, making the lifting operation more efficient and faster.

- Protection: A well-designed lifting system reduces the impact and vibrations on components during lifting, protecting them from damage.

-

Design Positioning and Load Adjustment Bolts for Bearing Housings

-

Design Adjustment Washers for Connection Surfaces with Height Changes

-

Design Locating Pins or Stops for Bolt Connections

-

Distinguish Between Field Welding and Factory Welding

- Field Welding: Typically done outdoors or at construction sites, where environmental conditions may be harsh (e.g., temperature variations, wind, high humidity, dust). These factors can affect welding quality and efficiency.

- Factory Welding: Conducted in a controlled factory environment where parameters like temperature, humidity, and wind speed are strictly regulated to ensure stability and quality.

- Specify Special Welding Requirements that Are Not Standard

- Section View to Reflect Oil Seal Orientation

- Design Double Nuts for Large Component Connections to Prevent Loosening

- Specify Areas Not to Be Painted

- Indicate Motion Range (Start and End Positions) and Trajectory for Moving Parts

- Safety Design for Working and Non-Working States

- Reinforce Load-Bearing Areas (e.g., Stiffeners) and Reduce Weight in Non-Load-Bearing Areas (e.g., Weight Reduction Holes)

- Stiffeners: Enhance the strength and rigidity of specific areas to withstand greater loads and stresses. Properly designed stiffeners can significantly improve structural load-bearing capacity and stability without increasing overall material usage.

- Weight Reduction Holes: Remove non-load-bearing material to lighten the overall weight while maintaining structural integrity. This helps lower product costs and improve energy efficiency and environmental performance.

- Ensure Comprehensive Design of Linear, Fit, and Geometric Tolerances

- Design Reasonable Machining Roughness:

Surface roughness reflects the irregularity of the micro-geometric shape of the processed surface, characterized by the spacing between peaks and valleys and minor unevenness. The smaller this irregularity, the higher the surface precision. - Accurately Document Technical Specifications